-

Quick View

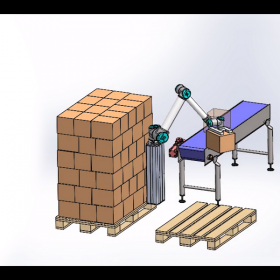

AUTOMATIC BOX FILLING

Devamını okuSINTERPACK has numerous references in both conventional (wrap around) and robotized (pick & place) box filling of packages, cans and jars, as well as the subsequent transport, handling and palletising of boxes or trays according to the required palletising patterns.

-

Quick View

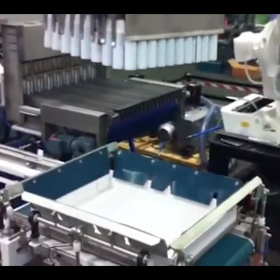

AUTOMATIC BOX FILLING OF BLISTERS

Devamını okuSINTERPACK has important references in box filling for blisters, as well as in the subsequent transport, handling and palletising of boxes according to the required palletising patterns.

-

Quick View

CANNED FOOD PALLETISING

Devamını okuSINTERPACK accumulates a few references in both conventional and robotised (pick & place) box filling of cans and jars, as well as in the subsequent transport, handling and palletising of boxes or trays according to required palletising patterns.

-

Quick View

COLLABORATIVE PALLETIZING CELL (CCPS)

Devamını okuCollaborative palletizing cell (CCPS). A machine, with which the company from Burgos aims to revolutionize the industrial robotics sector, by being able to work together with people without the need for a perimeter fence.

Robots are a key element of industry 4.0, they provide answers, with new production methods, to the main issues of our times.

Collaborative robots represent a new era in industrial robotics. They are light, flexible and easy to install; but their main virtue is that they are apt to work together with people, since they have security integrated as their own functionality. They cooperate with the operator to let him perform the tasks he performs best, avoiding dangerous, dirty or noisy jobs. Characteristics that represent a great advance in the improvement of competitiveness.

Despite its short life, the model proposed by Sinterpack has already been awarded the 2017 FAE innovation prize and the company is already working on the development of new collaborative packaging systems. This time using a claw similar to that of his older brother, but with the UR-5 robot, smaller and with less load capacity. -

Quick View

COLLABORATIVE ROBOTS

Devamını okuThe possibility of collaboration between humans and robots in a shared work space, without safety fencing or protection barriers of any kind, opens a challenging new work field, with uncountable opportunities and concepts for industry and production.

The collaborative robotics introduces four different safety basic principles in the human-robot collaboration relationship, described below:

1. Learning by manual guidance

The movements to be made by each section of the robotic arm are taught by the operator through physical guidance

2. Distance and speed monitoring

The robot predicts a collision with the operator by monitoring their speed and the distance of separation.

3. Monitored stop oriented to safety

Robots are programmed to stop or reduce their speed autonomously when the worker accesses the common area of work and continues to work once the worker has left the area.

4. Limitation of output and power

The contact pressure between the operator and the robot is technically reduced to an acceptable level.

The legal situation allows human-robot collaboration within certain limits. In any case, considering that, depending on the application, different elements might introduce different risks, systems with cobots require a risk evaluation and their corresponding certification of the complete system safety, provided by an accredited institution.

Our innovative nature has led us to develop, using this technology, our SPCC (Sinterpack’s Palletising Collaborative Cell), which was launched in May 2017.

The SPCC is equipped with a UR10 arm, of 10kg maximum load capacity, and a collaborative gripper with a suction pad, specifically designed by SINTERPACK for this application, weighing 1.5kg, which leaves a nominal load capacity of 8.5kg. It includes a double belt conveyor, for boxes dosage, at the entrance of the cell.

The footprint of the equipment is of 2.2 by 2.4 meters and its output reaches 7.5 cycles per minute in collaborative conditions. -

Quick View

DEPALLETISING OF PET BOTTLES

Devamını okuSINTERPACK has a number of references in depalletising of PET bottles.

-

Quick View

E2 PLASTIC CRATES PALLETISING

Devamını okuSINTERPACK has got innovative solutions for the integration of transport, handling and palletising / depalletising of packages within these sub-sectors, adapting our systems to the most extreme environmental conditions.

Whether through conventional solutions or robotised systems, or even through our innovative stacker-palletiser, able to work with both E2 plastic crates and cardboard boxes, we are able to offer our customers the best alternative adapted to their needs. -

Quick View

PALLETISING IN 8 STATIONS

Devamını okuIn the area of electric household appliances, SINTERPACK has developed and set up a cell, with a single robot, for the handling and palletising of induction hobs, capable to work simultaneously with 8 palletising stations. The system receives all the different products through the same entrance and separates the different references placing them in their corresponding station and delivering the finished pallets to the wrapping line.

-

Quick View

PALLETISING IN BOX

Devamını okuSINTERPACK has several references related to solutions for handling packets with delta robots (spider) and their subsequent introduction in box pallets using a full layer vacuum gripper.

-

Quick View

PALLETISING OF BAGS

Devamını okuThe anthropomorphic robots for palletising boxes or bags are an excellent solution for all types of stacking patterns. Thanks to their flexibility, it is possible to use these equipments serving several concurrent lines with different patterns and products. The products can be identified and palletised in different stations using innovative technical solutions.

SINTERPACK has numerous references in this field, including transport, homogenization and palletising of bags. These palletising solutions with anthropomorphic robots can reach a capacity of 1200-1800 bags/hour.

The design and materials of the grippers are very important because, by decreasing the mechanical resistance, the number of cycles of the robotised arm can be optimized, including the positioning of empty pallets or the placement of interlayers for the stabilisation of the load.

Other advantages of robotised palletising are the smaller total dimensions of the cells compared to conventional equipment, reduction of energy consumption and reduction of maintenance costs. -

Quick View

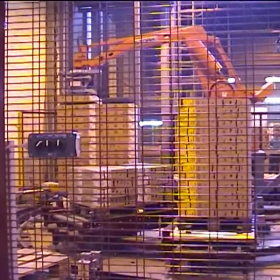

PALLETISING OF BOXES

Devamını okuThe anthropomorphic robots for palletising applications pose an excellent solution for all kind of stacking patterns. Thanks to their flexibility, it is possible to use these equipments serving several concurrent lines with different patterns and products. The products can be identified and palletised in different stations through innovative technical solutions.

The design and materials of the grippers are very important because, by decreasing the mechanical resistance, the number of cycles of the robotised arm can be optimized, including the positioning of empty pallets or the placement of interlayers for the stabilisation of the load. -

Quick View

PALLETISING OF BRIKS

Devamını okuSINTERPACK is the leader in end of line automation and robotisation in the dairy sector in Spain. Since the implementation of the first palletising robot in Leche Pascual in 1998, SINTERPACK has continued to grow in this sector, having installed more than 60 robotic cells and intervened in improvements and modernisation of multiple existing installations.

Every system is designed taking into account both the specific needs of each plant in terms of efficiency and cost savings, and the existing limitations of space, access, etc. always with the aim of providing our clients with the ability to stand out and gain competitiveness. -

Quick View

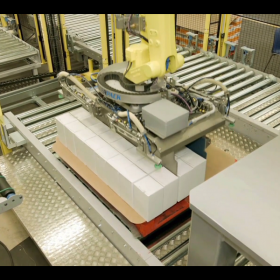

PALLETISING OF PAPER AND CELLULOSES

Devamını okuAs for the paper industry, we have got significant references in handling and palletising of paper reams.

Regarding celluloses, SINTERPACK has references in various plants for handling and palletising of extruded cellulose packages. -

Quick View

PALLETISING OF PET

Devamını okuSINTERPACK has several references in handling, placing in trays or carton cases and palletising of PET containers.

-

Quick View

PALLETISING OF SPRAY CANS

Devamını okuSINTERPACK has got references in handling, introduction in trays or cardboard cases, and palletising of spray containers.

-

Quick View

PALLETISING ON ¼ PALET

Devamını okuSINTERPACK has got its own development for the palletising in ¼ pallet, providing an innovative response to the real needs of supermarket shelves.

-

Quick View

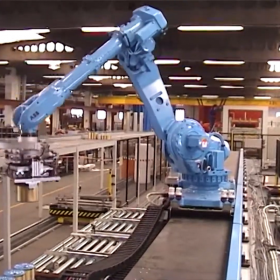

PALLETISING WITH ROBOTS ON A TRACK MOTION EQUIPMENT

Devamını okuWhen circumstances like room constraints or number of references require it, a robot mounted on a track motion system may be the best solution, ensuring reliable and effective utilisation of the robot’s capacity and maximizing the value of the automation investment. SINTERPACK has successfully developed some proposals using this system.

For the automotive sector, one of the most automated sectors in the industry, SINTERPACK has integrated, for example, a system for robotic palletising of coils, mounted on a track motion system, capable to simultaneously work with 28 palletising stations. The system respects the most stringent quality requirements and handles cable coils without touching the product. It is integrated in turn in the plant production IT system. -

Quick View

STACKER-PALLETISER

Devamını okuWhether through conventional solutions or robotised systems, or even through our innovative stacker-palletiser, able to work with both E2 plastic crates and cardboard boxes, we are able to offer our customers the best alternative adapted to their needs.