-

Quick View

2 Finger Tweezers

Devamını okuAdaptable two-finger plug + play grippers and easy to program for Collaborative robots. Three different models to suit your needs.

Characteristics

Easy to use

- Developed for Universal Robots

- Plug + Play

- Free programming software

Versatile

- Built-in position feedback

- 3 broad stroke options

- Multiple grip modes

They adapt to the needs of the industry

- Fast and solid

- Accurate and durable

- Validation of parts

specs

- Stroke (Programmable):

Hande-E: 50 mm

2F-85: 85 mm

2F-140: 140 mm - Gripping force (programmable):

Hande-E: 60 to 130 N

2F-85: 20 to 235 N

2F-140: 10 to 125 N - Shape-fit grip payload:

Hande-E: 5 kg

2F-85: 5 kg

2F-140: 2.5 kg - Friction grip payload:

Hande-E: 3 kg

2F-85: 5 kg

2F-140: 2.5 kg - Gripper mass:

Hande-E: 1 kg

2F-85: 0.9 kg

2F-140: 1 kg - Position resolution (fingertip):

Hande-E: 0.2mm

2F-85: 0.4 mm

2F-140: 0.6 mm - Closing speed (Programmable):

Hande-E: 20 to 150 mm / s

2F-85: 20 to 150 mm / s

2F-140: 30 to 250 mm / s - Communication protocol:

Hande-E: Modbus RTU (RS-485) - Communication protocol options:

Hande-E: Ethernet / IP, Modbus TCP,

PROFINET, DeviceNet,

Canopen, EtherCAT

-

Quick View

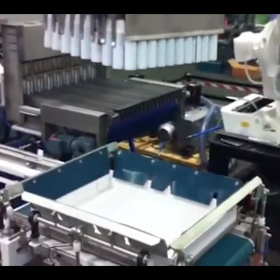

AUTOMATIC BOX FILLING

Devamını okuSINTERPACK has numerous references in both conventional (wrap around) and robotized (pick & place) box filling of packages, cans and jars, as well as the subsequent transport, handling and palletising of boxes or trays according to the required palletising patterns.

-

Quick View

AUTOMATIC BOX FILLING OF BLISTERS

Devamını okuSINTERPACK has important references in box filling for blisters, as well as in the subsequent transport, handling and palletising of boxes according to the required palletising patterns.

-

Quick View

BP – 150

Devamını okuSemi-automatic, compact and flexible side loading packer

Semi-automatic solution for side loading, modular, compact and flexible load. Designed for low per minute production speed.

With this generation of packers, the market needs in automating the end of line products whose regular forms are readily manageable at high production volumes are catered to.

The stack is made by lifting with side support, forming the different layers programmed with complete accuracy in terms of counting.

Cases should be placed manually on the front side waiting to be filled

Once the full cluster is obtained, the set of containers is conveyed to the inside of the case, leaving space for closing flaps and applying adhesive tape.

The BP-150 is a semi-automatic, modular, compact and flexible side packer, designed for low per minute production speed

PRODUCT INPUT:

Product feeding conveyor is 1000 mm long and 300 mm wide, with a working height of 910 mm. The feeder detects accumulation of containers, and sends a signal to stop the machine before any anomaly occurs.

STACKER:

Stacking of packages through a pneumatic lift, which builds up the levels on the tilting flap system with side guidance of the product, until the number of levels pre-set in the program is achieved.

The height of the containers in the entry position of the stacking should be 25 to 70 mm. For greater heights, the standard height of hatches should be amended.SHAPE OF CASE:

The case is made manually. Once it is formed and sealed from beneath, the case is placed against the mouth and the trigger is actuated to set the arm case.

INSERTION OF THE CASE:

Combined introducer group using pneumatic pusher, which with the help of a guide of the case flaps installed thereto, ensure transfer process of set of product packs into the case.

CASE OUTLET:

Automatic case outlet with positioning thereof on the output roller.

MAN/MACHINE INTERFACE:

All security or system failure elements, such as accumulation of product on the store conveyor, doors or protections not closed, presence of case, malformed case, lack of air pressure, etc. are displayed on a display screen built into the operating panel for quick location. Being an open system, the staff has access to counters, timers, etc. without the need of specialized personnel, because of the simplicity of its use. All electrical machine command is centralized in a PLC, allowing versatility and speed or system changes.

CHARACTERISTICS

- For packing of rigid parallelepiped containers that can be combined with each other

- case packaging introducer, with automatic position control, ready for closing.

- Rapidly changes the mechanical format and stores them in a PLC.

- No introduction device in the absence of case

- Electrical and mechanical protections as per regulations

- Designed for low case production per minute

- Valid for RSC case

- Simplicity and adaptability to different sizes and/or formats

-

Quick View

Camera

Devamını okuAn easy way to add machine vision to your robot. Camera setup in less than 30 minutes. It incorporates all the softwares to load the camera options in the robot. You will no longer need items to come in an orderly fashion to grab them.

Characteristics

Easy to use

- Plug + Play

- UR + certified products

- Free programming software

Control on the programming console:

- 2 instruction methods for custom objects

- No external PC required

- Powerful color validation

For industrial needs:

- Sealed and compact hardware

- Slim design that fits all UR joints

- Adjustable focus and lighting

Custom detection settings

- Adjust focus and built-in light to optimize programming and running conditions

Color validation

- Improve model detection and enable object classification during manipulation

- specs

- Focus radius: 70mm to infinity

- Integrated lighting: Two units (white and diffuse LED)

- Programmable parameters:

-Automatic and parametric programming of parts

-Editing edges, color validation

-Focusing, lighting on / off - Electric: Direct communication with the UR controller (via USB), and power supply from the controller (24V)

- Mass: 160 g

- Operating temperature: 0ºC to 50ºC

-

Quick View

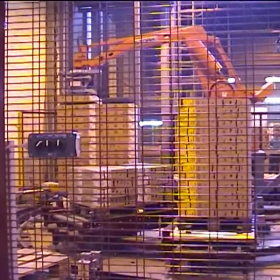

CANNED FOOD PALLETISING

Devamını okuSINTERPACK accumulates a few references in both conventional and robotised (pick & place) box filling of cans and jars, as well as in the subsequent transport, handling and palletising of boxes or trays according to required palletising patterns.

-

Quick View

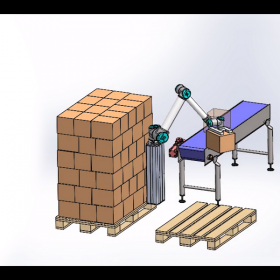

COLLABORATIVE PALLETIZING CELL (CCPS)

Devamını okuCollaborative palletizing cell (CCPS). A machine, with which the company from Burgos aims to revolutionize the industrial robotics sector, by being able to work together with people without the need for a perimeter fence.

Robots are a key element of industry 4.0, they provide answers, with new production methods, to the main issues of our times.

Collaborative robots represent a new era in industrial robotics. They are light, flexible and easy to install; but their main virtue is that they are apt to work together with people, since they have security integrated as their own functionality. They cooperate with the operator to let him perform the tasks he performs best, avoiding dangerous, dirty or noisy jobs. Characteristics that represent a great advance in the improvement of competitiveness.

Despite its short life, the model proposed by Sinterpack has already been awarded the 2017 FAE innovation prize and the company is already working on the development of new collaborative packaging systems. This time using a claw similar to that of his older brother, but with the UR-5 robot, smaller and with less load capacity. -

Quick View

COLLABORATIVE ROBOTS

Devamını okuThe possibility of collaboration between humans and robots in a shared work space, without safety fencing or protection barriers of any kind, opens a challenging new work field, with uncountable opportunities and concepts for industry and production.

The collaborative robotics introduces four different safety basic principles in the human-robot collaboration relationship, described below:

1. Learning by manual guidance

The movements to be made by each section of the robotic arm are taught by the operator through physical guidance

2. Distance and speed monitoring

The robot predicts a collision with the operator by monitoring their speed and the distance of separation.

3. Monitored stop oriented to safety

Robots are programmed to stop or reduce their speed autonomously when the worker accesses the common area of work and continues to work once the worker has left the area.

4. Limitation of output and power

The contact pressure between the operator and the robot is technically reduced to an acceptable level.

The legal situation allows human-robot collaboration within certain limits. In any case, considering that, depending on the application, different elements might introduce different risks, systems with cobots require a risk evaluation and their corresponding certification of the complete system safety, provided by an accredited institution.

Our innovative nature has led us to develop, using this technology, our SPCC (Sinterpack’s Palletising Collaborative Cell), which was launched in May 2017.

The SPCC is equipped with a UR10 arm, of 10kg maximum load capacity, and a collaborative gripper with a suction pad, specifically designed by SINTERPACK for this application, weighing 1.5kg, which leaves a nominal load capacity of 8.5kg. It includes a double belt conveyor, for boxes dosage, at the entrance of the cell.

The footprint of the equipment is of 2.2 by 2.4 meters and its output reaches 7.5 cycles per minute in collaborative conditions. -

Quick View

CP – 101

Devamını okuTop loading Pick & Place case packer

Top loading cartoning solution using the Pick & Place Cartesian system with forming, filling and closing of cases in a single monoblock.

The CP-101 is a top loading, compact and flexible case packer with Pick & Place cartesian system for forming, filling and closing cases or exhibitor cases in a single monoblock with. The filling of cases is performed by a pick & place mechanism with a simple gripping head with speed which is adjustable according to product type. The system is expandable depending on the required production output.

With this cartoning, the market needs in automating the end of line products whose irregular or unstable forms are not readily manageable at high production volumes are catered to.

-

Quick View

CP – 302

Devamını okuTop loading high speed Pick & Place case packer

A compact and flexible, top loading, Pick & Place cartoning solution for forming, filling and closing of cases for high speeds.

The CP-302 is a compact top loading and flexible case packer with Pick & Place cartesian system for forming, filling and closing cases or exhibitor cases. The filling of cases is performed by a pick & place mechanism with a triple gripping head with speed which is adjustable according to product type. The system is expandable, depending on the required production output.

With this case packing solution, the market needs in automating the end of line products whose irregular or unstable forms are not readily manageable at high production volumes are catered to.

-

Quick View

CP- 201

Devamını okuTop-loading medium and high speed Pick & Place case packer

Top loading cartoning solution using the Pick & Place Cartesian system with forming, filling and closing of cases at medium and high speeds.

The CP-201 is a top loading compact and flexible case packer with Pick & Place cartesian system for forming, filling and closing cases or exhibitor cases. The filling of cases is performed by a pick & place mechanism with a double gripping head with speed which is adjustable according to product type. The system is expandable, depending on the required production output.

With this cartoning, the market needs in automating the end of line products whose irregular or unstable forms are not readily manageable at high production volumes are catered to.

-

Quick View

CR – 101

Devamını okuTop load robotic cartoning solution for forming, filling and closing of cases in a single monoblock

The CR-101 is a top loading robotic, compact and flexible case packing solution for forming, filling and closing of cases or exhibitor cases in a single monoblock. The filling of cases is done by robot, adjusting speed according to product type, with expandable capacity depending on the required production output.

With this case packing solution, the market needs in automating the end of line products whose irregular or unstable forms are not readily manageable at high production volumes is catered to. -

Quick View

CR – 201

Devamını okuHigh speed robotic top loading case packer

Top load robotic cartoning solution for forming, filling and closing of cases in a single monoblock at high speed.

The CR-201 is a top loading robotic, compact and flexible case packing solution for forming, filling and closing of cases or exhibitor cases in a single monoblock. The filling of cases is done by 2 robots, adjusting speed according to product type, with expandable capacity depending on the required production output. Specifically designed to work at high speeds .

With this high speed of cartoning, the market needs in automating the end of line products whose irregular or unstable forms are not readily manageable at high production volumes is catered to.

-

Quick View

D – 100

Devamını okuTop loading Pick & Place multiple station packer

Solution Top loading packer using Pick & Place Cartesian multiple case filling stations.

The D-100 is a top packer with Pick & Place Cartesian system consisting of multiple case filling stations. The filling of cases is performed by a pick & place mechanism which supports several heads with speed which is adjustable according to product type. The system is expandable, depending on the required production output.

The new generation DELTA machines are designed to solve any needs that arise in the final line by automating the packing phase.

SERIE 100

Flexible in its applications, the D-100 packer can be equipped with multiple power lines, thus also developing functional synchronization of the unit to a single line, regardless of the packing function.

An additional mechanism allows rotation of the suction head to deposit the containers at different positions on each floor or line. The spindle includes packaging tape or product entry element. In the scroll cases, the pickup element performs a twist on its axis by placing the containers at 90° or 180° from the initial position.

Unit formation and closure of independent cases.

The D-100 packer, can be incorporated into the available spaces in each case, depending on the precise characteristics, the configuration that best suits the needs of both techniques is the economic preference. The design of this equipment, together with its easy adaptability to new formats or final submissions, provides a very good versatility for future applications.

Designed for higher production volumes and loading several cases for each work cycle. It is also equipped with various power system products, thereby making it multi-functional.

Several specific systems can be incorporated into the computer system for food and packaging: bags, doypacks, bottles, envelopes, cases, trays, jars, flow packs, etc. There is a solution for each case.CHARACTERISTICS

- Reaches an output of up to 25 cases/minute

- Multiple case filling stations

- Flexible solution

- Up to 3 cases/cycle

- Optional case placement unit

- Closing of case for optional seal or hot glue

- Spindle rotation option

- Valid for WRAPPING cases such as RSC

- Quick format change

-

Quick View

D – 100

Devamını okuTop loading Pick & Place multiple station packer

Solution Top loading packer using Pick & Place Cartesian multiple case filling stations.

The D-100 is a top packer with Pick & Place Cartesian system consisting of multiple case filling stations. The filling of cases is performed by a pick & place mechanism which supports several heads with speed which is adjustable according to product type. The system is expandable, depending on the required production output.

The new generation DELTA machines are designed to solve any needs that arise in the final line by automating the packing phase.

SERIE 100

Flexible in its applications, the D-100 packer can be equipped with multiple power lines, thus also developing functional synchronization of the unit to a single line, regardless of the packing function.

An additional mechanism allows rotation of the suction head to deposit the containers at different positions on each floor or line. The spindle includes packaging tape or product entry element. In the scroll cases, the pickup element performs a twist on its axis by placing the containers at 90° or 180° from the initial position.

Unit formation and closure of independent cases.

The D-100 packer, can be incorporated into the available spaces in each case, depending on the precise characteristics, the configuration that best suits the needs of both techniques is the economic preference. The design of this equipment, together with its easy adaptability to new formats or final submissions, provides a very good versatility for future applications.

Designed for higher production volumes and loading several cases for each work cycle. It is also equipped with various power system products, thereby making it multi-functional.

Several specific systems can be incorporated into the computer system for food and packaging: bags, doypacks, bottles, envelopes, cases, trays, jars, flow packs, etc. There is a solution for each case.CHARACTERISTICS

- Reaches an output of up to 25 cases/minute

- Multiple case filling stations

- Flexible solution

- Up to 3 cases/cycle

- Optional case placement unit

- Closing of case for optional seal or hot glue

- Spindle rotation option

- Valid for WRAPPING cases such as RSC

- Quick format change

-

Quick View

D – 200

Devamını okuPick & Place top loading packer with integrated case former

A top Pick & Place packing solution with integrated case former, designed for medium and low capacity.

The D-200 is a Pick & Place top packer with integrated case former, designed for medium and low capacities. The filling of cases is performed by a pick & place mechanism which supports several heads with speed which is adjustable according to product type. The system is expandable, depending on the required production output.

The new generation DELTA machines are designed to solve any needs that arise in the final line by automating the packing phase.

SERIE 200

Flexible in its applications, the D-200 packer can be equipped with multiple power lines, thus also developing functional synchronization of the unit to a single line, regardless of the packing function.

An additional mechanism allows rotation of the suction head to deposit the containers at different positions on each floor or line. The spindle includes packaging tape or product entry element. In the scroll cases, the pickup element performs a twist on its axis by placing the containers at 90° or 180° from the initial position.

Unit with integrated case former

The D-200 packer, can be incorporated into the available spaces in each case, depending on the precise characteristics, the configuration that best suits the needs of both techniques is the economic preference. The design of this equipment, together with its easy adaptability to new formats or final submissions, provides a very good versatility for future applications.

Several specific systems can be incorporated into the computer system for food and packaging: bags, doypacks, bottles, envelopes, cases, trays, jars, flow packs, etc. There is a solution for each case.

CHARACTERISTICS

- Reaches an output of up to 10 cases/minute

- Flexible solution

- Up to 1 case/cycle

- Unit with integrated case former

- Closing of case for optional seal or hot glue

- Spindle rotation option

- Valid for RSC case

- Quick format change

- Occupies small amount of space

- Designed for low and medium capacity

-

Quick View

D – 300

Devamını okuTop loading with packer Pick & Place for high speeds

Superior solution for packing systems using Pick & Place Cartesian multiple case filling stations, especially for high speeds.

The D-300 is a top packer with Pick & Place Cartesian system consisting of multiple case filling stations. The filling of cases is performed by a pick & place mechanism, with double leads, which supports several heads with speed which is adjustable according to product type. The system is expandable, depending on the required production output.

Its main feature is the flexibility to operate different packing concepts in a single machine. Going from a top loading to a side loading machine is a matter of few minutes in special cases.

This packer incorporates an external element which enables the adaptation of a top lid in cardboard cases intended for exhibiting.

The new generation DELTA machines are designed to solve any needs that arise in the final line by automating the packing phase.

SERIE 300

Flexible in its applications, the D-300 packer can be equipped with multiple power lines, thus also developing functional synchronization of the unit to a single line, regardless of the packing function.

An additional mechanism allows rotation of the suction head to deposit the containers at different positions on each floor or line. The spindle includes packaging tape or product entry element. In the scroll cases, the pickup element performs a twist on its axis by placing the containers at 90° or 180° from the initial position.

Unit formation and closure of independent cases.

The D-300 packer, can be incorporated into the available spaces in each case, depending on the precise characteristics, the configuration that best suits the needs of both techniques is the economic preference. The design of this equipment, together with its easy adaptability to new formats or final submissions, provides a very good versatility for future applications.

Designed for higher production volumes and loading several cases for each work cycle. It is also equipped with various power system products, thereby making it multi-functional.

Several specific systems can be incorporated into the computer system for food and packaging: bags, doypacks, bottles, envelopes, cases, trays, jars, flow packs, etc. There is a solution for each case.

CHARACTERISTICS

- Reaches an output of up to 30 cases/minute

- Multiple case filling stations

- Flexible solution

- Up to 6 cases/cycle

- Optional case placement unit

- Closing of case for optional seal or hot glue

- Spindle rotation option

- Valid for WRAPPING cases such as RSC

- Double guided spindle

- Designed to operate at high speeds

- Quick format change

-

Quick View

D – 300

Devamını okuTop loading with packer Pick & Place for high speeds

Superior solution for packing systems using Pick & Place Cartesian multiple case filling stations, especially for high speeds.

The D-300 is a top packer with Pick & Place Cartesian system consisting of multiple case filling stations. The filling of cases is performed by a pick & place mechanism, with double leads, which supports several heads with speed which is adjustable according to product type. The system is expandable, depending on the required production output.

Its main feature is the flexibility to operate different packing concepts in a single machine. Going from a top loading to a side loading machine is a matter of few minutes in special cases.

This packer incorporates an external element which enables the adaptation of a top lid in cardboard cases intended for exhibiting.

The new generation DELTA machines are designed to solve any needs that arise in the final line by automating the packing phase.

SERIE 300

Flexible in its applications, the D-300 packer can be equipped with multiple power lines, thus also developing functional synchronization of the unit to a single line, regardless of the packing function.

An additional mechanism allows rotation of the suction head to deposit the containers at different positions on each floor or line. The spindle includes packaging tape or product entry element. In the scroll cases, the pickup element performs a twist on its axis by placing the containers at 90° or 180° from the initial position.

Unit formation and closure of independent cases.

The D-300 packer, can be incorporated into the available spaces in each case, depending on the precise characteristics, the configuration that best suits the needs of both techniques is the economic preference. The design of this equipment, together with its easy adaptability to new formats or final submissions, provides a very good versatility for future applications.

Designed for higher production volumes and loading several cases for each work cycle. It is also equipped with various power system products, thereby making it multi-functional.

Several specific systems can be incorporated into the computer system for food and packaging: bags, doypacks, bottles, envelopes, cases, trays, jars, flow packs, etc. There is a solution for each case.

CHARACTERISTICS

- Reaches an output of up to 30 cases/minute

- Multiple case filling stations

- Flexible solution

- Up to 6 cases/cycle

- Optional case placement unit

- Closing of case for optional seal or hot glue

- Spindle rotation option

- Valid for WRAPPING cases such as RSC

- Double guided spindle

- Designed to operate at high speeds

- Quick format change

-

Quick View

D – 400

Devamını okuPick & Place top packer with integrated case forming & sealing

Superior solution for packing systems using Pick & Place multiple case filling stations in a single monoblock. With integrated forming and sealing of cases, designed specifically for small spaces.

Superior solution for packing systems using Pick & Place multiple case filling stations in a single monoblock. With integrated forming and sealing of cases, designed specifically for small spaces. The filling of cases is performed by a pick & place mechanism which supports several heads with speed which is adjustable according to product type. The system is expandable, depending on the required production output.

The new generation DELTA machines are designed to solve any needs that arise in the final line by automating the packing phase.

SERIE 400

Flexible in its applications, the D-400 packer can be equipped with multiple power lines, thus also developing functional synchronization of the unit to a single line, regardless of the packing function.

An additional mechanism allows rotation of the suction head to deposit the containers at different positions on each floor or line. The spindle includes packaging tape or product entry element. In the scroll cases, the pickup element performs a twist on its axis by placing the containers at 90° or 180° from the initial position.

The D-400 packer, can be incorporated into the available spaces in each case, depending on the precise characteristics, the configuration that best suits the needs of both techniques is the economic preference. The design of this equipment, together with its easy adaptability to new formats or final submissions, provides a very good versatility for future applications.

Several specific systems can be incorporated into the computer system for food and packaging: bags, doypacks, bottles, envelopes, cases, trays, jars, flow packs, etc. There is a solution for each case.

CHARACTERISTICS

- Reaches an output of up to 10 cases/minute

- Flexible solution

- Up to 1 case/cycle

- Unit with integrated case former

- Closing of case with seal or hot glue

- Spindle rotation option

- Valid for RSC case

- Quick format change

- Designed for medium and high capacities

- Occupies small amount of space

- Multiple case filling stations

-

Quick View

D – 500

Devamını okuPick & Place top packer with integrated case former

Superior solution for packing systems using Pick & Place multiple case filling stations. With integrated case formers, designed for medium and high capacities.

The D-500 is a Pick & Place top packer consisting of multiple case filling stations. It also has integrated case forming, designed for medium and low capacities. The filling of cases is performed by a pick & place mechanism which supports several heads with speed which is adjustable according to product type. The system is expandable, depending on the required production output.

The new generation DELTA machines are designed to solve any needs that arise in the final line by automating the packing phase.

SERIE 500

Flexible in its applications, the D-500 packer can be equipped with multiple power lines, thus also developing functional synchronization of the unit to a single line, regardless of the packing function.

An additional mechanism allows rotation of the suction head to deposit the containers at different positions on each floor or line. The spindle includes packaging tape or product entry element. In the scroll cases, the pickup element performs a twist on its axis by placing the containers at 90° or 180° from the initial position.

The D-500 packer, can be incorporated into the available spaces in each case, depending on the precise characteristics, the configuration that best suits the needs of both techniques is the economic preference. The design of this equipment, together with its easy adaptability to new formats or final submissions, provides a very good versatility for future applications.

Several specific systems can be incorporated into the computer system for food and packaging: bags, doypacks, bottles, envelopes, cases, trays, jars, flow packs, etc. There is a solution for each case.

CHARACTERISTICS

- Reaches an output of up to 12 cases/minute

- Flexible solution

- Up to 2 cases/cycle

- Unit with integrated case former

- Closing of case for optional seal or hot glue

- Spindle rotation option

- Valid for RSC case

- Quick format change

- Designed for medium and high capacities

-

Quick View

D – 600

Devamını okuSide and top loading Pick & Place case packer

Top and side solution for packing systems using Pick & Place Cartesian multiple case filling stations, especially for high speeds.

The D-600 is a top packer with Pick & Place Cartesian system consisting of multiple case filling stations. The filling of cases is performed by a pick & place mechanism, with double leads, which supports several heads with speed which is adjustable according to product type. The system is expandable, depending on the required production output.

Its main feature is the flexibility to operate different packing concepts in a single machine. Going from a top loading to a side loading machine is a matter of few minutes in special cases.

With this case packing model a new application for flexible side packaging has been developed, where the machine can be fit on a flat product and on product stands. For this new packing system, we have two different modes

Placing containers on a plain: Using a Pick & Place system the bags are positioned directly inside the flat case. Top packing allows grouping in levels. Thanks to double stacker and three fits for cases it is possible to reach a high packing speed (Highspeed).

Vertical placement of containers: Inclusion of side loading module, combined with the pick & place system, allows a final vertical product presentation inside the cases.

This system carries out clustering operation through “pick & place” function in a case of side insertion, turning empty cases 90º and introducing the product in the same by a mechanical pusher.

The set consists of:

Product receiving drawer can accommodate a group consisting of:

- Base plate with adjustable side rails on which floor to floor clusters are formed.

- side press.

- Introducer of case clusters through servo drive Moves the group to insert it into the case.

Case opening: Articulated opening for the transfer of product to the the case. When opened it uses force to ensure squareness and correct positioning of the side case. After filling the case, the conveyor returns to its horizontal position.

- System on the side side of the case for positioning the grouping drawer to prevent overturning.

Standard case conveyor machine is replaced by a pivoting conveyor. The pivoting conveyor is provided with a side press for fixing the empty cases and tipping system for directed placing of the cases on the opposite side of the mouth

This packer incorporates an external element which enables the adaptation of a top lid in cardboard cases intended for exhibiting.

The new generation DELTA machines are designed to solve any needs that arise in the final line by automating the packing phase.

SERIE 600

Flexible in its applications, the D-600 packer can be equipped with multiple power lines, thus also developing functional synchronization of the unit to a single line, regardless of the packing function.

An additional mechanism allows rotation of the suction head to deposit the containers at different positions on each floor or line. The spindle includes packaging tape or product entry element. In the scroll cases, the pickup element performs a twist on its axis by placing the containers at 90° or 180° from the initial position.

Unit formation and closure of independent cases.

The D-600 packer, can be incorporated into the available spaces in each case, depending on the precise characteristics, the configuration that best suits the needs of both techniques is the economic preference. The design of this equipment, together with its easy adaptability to new formats or final submissions, provides a very good versatility for future applications.

Designed for higher production volumes and loading several cases for each work cycle. It is also equipped with various power system products, thereby making it multi-functional.

Several specific systems can be incorporated into the computer system for food and packaging: bags, doypacks, bottles, envelopes, cases, trays, jars, flow packs, etc. There is a solution for each case.

CHARACTERISTICS

- Reaches an output of up to 30 cases/minute

- Multiple case filling stations

- Flexible solution

- Up to 6 cases/cycle

- Optional case placement unit

- Closing of case for optional seal or hot glue

- Spindle rotation option

- Valid for WRAPPING cases such as RSC

- Double guided spindle

- Designed to operate at high speeds

- Quick format change

- Allows both top and side packing

- Single, double or triple packing

-

Quick View

D – 600

Devamını okuSide and top loading Pick & Place case packer

Top and side solution for packing systems using Pick & Place Cartesian multiple case filling stations, especially for high speeds.

The D-600 is a top packer with Pick & Place Cartesian system consisting of multiple case filling stations. The filling of cases is performed by a pick & place mechanism, with double leads, which supports several heads with speed which is adjustable according to product type. The system is expandable, depending on the required production output.

Its main feature is the flexibility to operate different packing concepts in a single machine. Going from a top loading to a side loading machine is a matter of few minutes in special cases.

With this case packing model a new application for flexible side packaging has been developed, where the machine can be fit on a flat product and on product stands. For this new packing system, we have two different modes

Placing containers on a plain: Using a Pick & Place system the bags are positioned directly inside the flat case. Top packing allows grouping in levels. Thanks to double stacker and three fits for cases it is possible to reach a high packing speed (Highspeed).

Vertical placement of containers: Inclusion of side loading module, combined with the pick & place system, allows a final vertical product presentation inside the cases.

This system carries out clustering operation through “pick & place” function in a case of side insertion, turning empty cases 90º and introducing the product in the same by a mechanical pusher.

The set consists of:

Product receiving drawer can accommodate a group consisting of:

- Base plate with adjustable side rails on which floor to floor clusters are formed.

- side press.

- Introducer of case clusters through servo drive Moves the group to insert it into the case.

Case opening: Articulated opening for the transfer of product to the the case. When opened it uses force to ensure squareness and correct positioning of the side case. After filling the case, the conveyor returns to its horizontal position.

- System on the side side of the case for positioning the grouping drawer to prevent overturning.

Standard case conveyor machine is replaced by a pivoting conveyor. The pivoting conveyor is provided with a side press for fixing the empty cases and tipping system for directed placing of the cases on the opposite side of the mouth

This packer incorporates an external element which enables the adaptation of a top lid in cardboard cases intended for exhibiting.

The new generation DELTA machines are designed to solve any needs that arise in the final line by automating the packing phase.

SERIE 600

Flexible in its applications, the D-600 packer can be equipped with multiple power lines, thus also developing functional synchronization of the unit to a single line, regardless of the packing function.

An additional mechanism allows rotation of the suction head to deposit the containers at different positions on each floor or line. The spindle includes packaging tape or product entry element. In the scroll cases, the pickup element performs a twist on its axis by placing the containers at 90° or 180° from the initial position.

Unit formation and closure of independent cases.

The D-600 packer, can be incorporated into the available spaces in each case, depending on the precise characteristics, the configuration that best suits the needs of both techniques is the economic preference. The design of this equipment, together with its easy adaptability to new formats or final submissions, provides a very good versatility for future applications.

Designed for higher production volumes and loading several cases for each work cycle. It is also equipped with various power system products, thereby making it multi-functional.

Several specific systems can be incorporated into the computer system for food and packaging: bags, doypacks, bottles, envelopes, cases, trays, jars, flow packs, etc. There is a solution for each case.

CHARACTERISTICS

- Reaches an output of up to 30 cases/minute

- Multiple case filling stations

- Flexible solution

- Up to 6 cases/cycle

- Optional case placement unit

- Closing of case for optional seal or hot glue

- Spindle rotation option

- Valid for WRAPPING cases such as RSC

- Double guided spindle

- Designed to operate at high speeds

- Quick format change

- Allows both top and side packing

- Single, double or triple packing

-

Quick View

DEPALLETISING OF PET BOTTLES

Devamını okuSINTERPACK has a number of references in depalletising of PET bottles.

-

Quick View

E2 PLASTIC CRATES PALLETISING

Devamını okuSINTERPACK has got innovative solutions for the integration of transport, handling and palletising / depalletising of packages within these sub-sectors, adapting our systems to the most extreme environmental conditions.

Whether through conventional solutions or robotised systems, or even through our innovative stacker-palletiser, able to work with both E2 plastic crates and cardboard boxes, we are able to offer our customers the best alternative adapted to their needs. -

Quick View

EC -15

Devamını okuSide loading of case with continuous advance

Case packing solution for side loading with continuous advance, with forming, filling and closing of cases in a single monoblock at high speeds.

The EC-15 is a compact and flexible continuously progressing side loading cartoner for forming, filling and closing of cases in a single monoblock for high speed. The filling of cases is done by a pusher, adjusting speed according to product type, with expandable capacity depending on the required production output.

Intermittent case packer, EC-15 can handle any type of cardboard, including micro corrugated cardboard, with flaps closed by Hot-Melt.

The equipment can be completed with a standard automatic filling for a variety of products or specially designed by our engineering team system.

Quick change of format using adjustments equipped with strips or counters.

Side case loading system achieves speeds of 125 cases per minute.

Product loading is performed by rotating mechanical thrusters that move product to the product buckets inside the case. This system allows full control of the product during loading, especially where they are flexible.

CHARACTERISTICS

- Double rotary head for vacuum opening of carton

- If there is no product, no carton is formed

- The device stops the machine if an overload occurs

- The buckets make a progressive side movement to touch the tip of the carton

- Product grouped by mechanical rotary pushers

- Closing carton by means of a Hot Melt applicator

- Electronic Speed control

- All machine functions are controlled by a PLC

- All doors are closed by a safety interlock, which causes the machine to stop when any of the doors is opened

-

Quick View

ECI-20

Devamını okuSide loading of case with intermittent advance

Case packing solution for side loading with intermittent progress, with forming, filling and closing of cases in a single monoblock.

ECI-20 is a compact and flexible side loading compact case packer with intermittent progress, for forming, filling and closing of cases in a single monoblock. The filling of cases is done by a pusher, adjusting speed according to product type, with expandable capacity depending on the required production output.

Intermittent case packer, ECI-20 can handle any type of cardboard, including micro corrugated cardboard, with flaps closed by Hot-Melt.

The cartoner can be completed with a standard automatic filling for a variety of products or specially designed by our engineering team system.

Quick change of format using adjustments equipped with strips or counters.

Side case loading system achieves speeds of 55 cases per minute.

CHARACTERISTICS

- If there is no product, no carton is formed

- If the carton is not formed, the product is rejected at the end of the line

- The device stops the machine if an overload occurs

- Closing carton by means of a Hot Melt applicator

- Digital indicator of production.

- All machine functions are controlled by a PLC

- All doors are closed by a safety interlock, which causes the machine to stop when any of the doors is opened

-

Quick View

FI – 1

Devamını okuCompact and flexible bottom loading case packer

Solution for bottom loading, modular, compact and flexible case packer Designed for medium per minute case production, all in a single monoblock.

The FI-1 is bottom loading, modular, compact and flexible case packer, designed for medium per minute case production, all in a single monoblock

The FI-1 equipment is designed specifically for packing products that need to be placed in the carton, maintaining the same position from packaging to the point of sale. Aerosols, bottles, pizza cases, biscuit cans, are some of the applications of the bottom loading equipment, which are characterised by special stacking modules for each product, and achieve high production yields.

Design and robust construction. They are designed for efficient and safe operation, simple and quick handling.

Easy format change, as well as reliability in the opening and management of the cases are the benefits that increase the efficiency of this equipment

Design and robust construction. They are designed for efficient and safe operation, simple and quick handling.

Easy format change, as well as reliability in the opening and management of the cases are the benefits that increase the efficiency of this equipment

An accessible and user-friendly design, plan for the grouping of containers, forming, filling and closing of cases in a single compact unit.

Ergonomic case store and large capacity

The machine incorporates a forced opening of the cases to ensure the correct position at the filling station and transfer to the sealing station.

Information Management: A powerful software developed by our technical team allows you total control over the device functions. You can also perform simple formatting changes through the incorporated touch screen. Through this, it is possible to verify production efficiency for shifts or slots, making it an effective analytical instrument. It is ready to integrate various lines of work according to the standard OMAC.

CASE MAGAZINE:

Inclined storage of cartons. Store length 630 mm. When the store is empty (or there are an insufficient number of cases for smooth operation), the machine is stopped and a visual signal warns the operator of the lack of cases. Optionally you can install an additional detection of the minimum number of cases that must always be present at the store so that the operator can reload before a machine stop.

SHAPE OF CASE:

Extraction of folded cartons using suction cups installed on a horizontal semicircular pneumatic arm Forced opening of the case by a suction cup system and a mechanism for side squaring with presence and formation detection of the case.

INSERTION OF THE CASE:

Shifting of the group from the lowering platform to the bottom of the case through pneumatically operated pusher Combined introducer group using pneumatic lift, which with the help of a guide of the case flaps installed thereto, ensure transfer process of set of product packs into the case..

PRODUCTION:

The formation unit and closing cases can reach an output of up to 9 cases per minute and the whole capacity will depend on the product and the group.

MAN/MACHINE INTERFACE

All security or system failure elements, such as accumulation of product on the store conveyor, poorly sealed doors or protections, presence of case, malformed case, lack of air pressure, etc are displayed on a touchscreen built into the control panel for quick location. The touch screen performs the function of man/machine interface, helping to quickly solve any problems which may have occurred in machine because of two utilities:

· Editing of error messages

· Fault locationBeing an open system, the staff has access to counters, timers, etc. without the need of specialized personnel, because of the simplicity of its use. The system offers the possibility of giving a complete history of the state of the machine:

Number of cycles. Number of cases. Number of case failures. Number of introduction failures. Hours of machine running. All electrical machine command is centralized in a PLC, allowing versatility and speed or system changes. Number of introduction failures. Hours of machine running. All electrical machine command is centralized in a PLC, allowing versatility and speed or system changes.CHARACTERISTICS

- Unit for forming, filling and closing of case

- Occupies small amount of space

- Rapidly changes the mechanical format and stores them in a PLC.

- No introduction device in the absence of case

- Electrical and mechanical protections as per regulations

- Designed for medium per minute case production

- Valid for RSC case

- Reaches an output of up to 9 cases/minute

-

Quick View

FI – 5

Devamını okuCompact and flexible bottom loading packer

Bottom loading, modular, compact and flexible case packing solution. Designed for medium per minute case production, all in a single monoblock.

The FI-5 is a bottom loading, modular, compact and flexible packer, designed for medium per minute case production, all in a single monoblock

The FI-5 equipment is designed specifically for packing products that need to be placed in the carton, maintaining the same position from packaging to the point of sale. Aerosols, bottles, pizza cases, biscuit cans, are some of the applications of the bottom loading equipment, which are characterized by special stacking modules for each product, and achieve high production yields.

Design and robust construction. They are designed for efficient and safe operation, simple and quick handling.

Easy format change, as well as reliability in the opening and management of the cases are the benefits that increase the efficiency of this equipment

An accessible and user-friendly design, intended for the grouping of containers, forming, filling and closing of cases in a single compact unit.

Ergonomic case magazine of large capacity

The machine includes a forced opening of the cases to ensure the correct position at the filling station and subsequent transfer to the sealing station.

Information Management: A powerful software developed by our technical team allows you to have total control over the device functions. You can also perform simple formatting changes through the incorporated touch screen. Through this, it is possible to verify production efficiency for shifts or slots, making it an effective analytical instrument. It is equipped to integrate various lines of work according to the standard OMAC.

CASE MAGAZINE:

Inclined stacking of cartons. Magazine length 630 mm. When the store is empty (or there are an insufficient number of cases for smooth operation), the machine is stopped and a visual signal warns the operator of the lack of cases. Optionally, you can implement an additional detection of the minimum number of cases that must always be present at the store so that the operator can reload before a machine stop.

SHAPE OF CASE:

Extraction of folded cartons using suction cups installed on a horizontal semicircular pneumatic arm Forced opening of the case by a suction cup system and a mechanism for side squaring with presence and formation detection of the case.

INSERTION OF THE CASE:

Shifting of the group from the lowering platform to the bottom of the case through pneumatically operated pusher Combined introducer group using pneumatic lift, which with the help of a guide of the case flaps installed thereto, ensure transfer process of set of product packs into the case.

PRODUCTION:

The formation unit and closing cases can reach an output of up to 9 cases per minute and the whole capacity will depend on the product and the group.

MAN/MACHINE INTERFACE

All security or system failure elements, such as accumulation of product on the store conveyor, poorly sealed doors or protections, presence of case, malformed case, lack of air pressure, etc are displayed on a touchscreen built into the control panel for quick location.

The touch screen performs the function of man/machine interface, helping to quickly solve any problems which may have occurred in machine because of two utilities:

· Editing of error messages

· Fault locationBeing an open system, the staff has access to counters, timers, etc. without the need of specialized personnel, because of the simplicity of its use.

The system offers the possibility of giving a complete history of the state of the machine: Number of cycles. Number of cases. Number of case failures. Number of insertion failures. Hours of machine running. All electrical machine command is centralized in a PLC, allowing versatility and speed or system changes. Number of introduction failures. Hours of machine running.

All electrical machine command is centralized in a PLC, allowing versatility and speed or system changes.CHARACTERISTICS

- Unit for forming, filling and closing of case

- Occupies small amount of space

- Rapidly changes the mechanical format and stores them in a PLC.

- No introduction device in the absence of case

- Electrical and mechanical protections as per regulations

- Designed for medium per minute case production

- Valid for RSC case

- Reaches an output of up to 6 cases/minute

-

Quick View

FL – 3

Devamını okuMedium/high capacity compact and flexible side loading packer

Solution for side loading, modular, compact and flexible case packer. Designed for medium/high per minute case production, all in a single monoblock.

The FL-3 is side loading, modular, compact and flexible packer, designed for medium/high per minute case production, all in a single monoblock

With this generation of packers, the market needs in automating the end of line products whose regular forms are readily manageable at high production volumes are catered to.

Unit for side loading case packer with high speed case erector of three stations allows incorporation of any power system or stacking of containers according to the characteristics of the same.

A renewed highly accessible design for easy operation that supports a variety of possible configurations depending on the type of product specifications and the required production speed. High performance equipment to work with high standards and excellent production efficiency. An accessible and user-friendly design, plan for the grouping of containers, forming, filling and closing of cases in a single compact unit.

Lifting or lowering carriers are available for the rigid or flexible packing of cases and specific power systems for packaging cannot be combined with each other. Ergonomic case store and large capacity. The machine incorporates a forced opening of the cases to ensure the correct position at the filling station and transfer to the sealing station. Closing of cases may be effected by adhesive tape, hot glue application or combination of both systems.

CASE MAGAZINE:

Horizontal case store with motor. store length 1000 mm. As the cases are removed from the system, a case presence detector causes the progress of the tape ensuring that the product is always ready for removal. When the store is empty (or there are an insufficient number of cases for smooth operation), the machine is stopped and a visual signal warns the operator of the lack of cases. Optionally you can install an additional detection of the minimum number of cases that must always be present at the store so that the operator can reload before a machine stop.

SHAPE OF CASE:

Removing the unit by folding cartons using suckers installed on a semicircular arm with mechanical movement. Forced opening of the case by a suction cup system and a mechanism for side squaring with presence and formation detection of the case.

DRAGGING OF THE CASE:

Transporting pre-opened case to the packaging station through a system of drag chains.

INSERTION OF THE CASE:

Combined introducer group using pneumatic pusher, which with the help of a guide of the case flaps installed thereto, ensure transfer process of set of product packs into the case.

PRODUCTION:

The equipment can absorb normal production of 17 cases per minute.

INTERFACE HOMBRE / MÁQUINA:

All security or system failure elements, such as accumulation of product on the store conveyor, poorly sealed doors or protections, presence of case, malformed case, lack of air pressure, etc are displayed on a touchscreen built into the control panel for quick location. The touch screen performs the function of man/machine interface, helping to quickly solve any problems which may have occurred in machine because of two utilities: Editing of error messages. Fault location. Being an open system, the staff has access to counters, timers, etc. without the need of specialized personnel, because of the simplicity of its use. The system offers the possibility of giving a complete history of the state of the machine: Number of cycles. Number of cases. Number of case failures. Number of introduction failures. Hours of machine running. All electrical machine command is centralized in a PLC, allowing versatility and speed or system changes.

CHARACTERISTICS

- Three loading stations: forming, filling and closing of cases

- Occupies small amount of space

- Rapidly changes the mechanical format and stores them in a PLC.

- No introduction device in the absence of case

- Electrical and mechanical protections as per regulations

- Designed for medium/high per minute case production

- Valid for RSC case

- Reaches an output of up to 17 cases/minute

-

Quick View

FL – 4

Devamını okuHigh capacity, compact and flexible side loading packer

Solution for side loading, modular, compact and flexible case packer. Designed for high per minute case production, all in a single monoblockk.

The FL-4 is a side loading, modular, compact and flexible packer, designed for high per minute case production, all in a single monoblockk

With this generation of packers, the market needs in automating the end of line products whose regular forms are readily manageable at high production volumes are catered to.

Unit for side loading case packer with high speed case erector of four stations allows incorporation of any power system or stacking of containers according to the characteristics of the same.

A renewed highly accessible design for easy operation that supports a variety of possible configurations depending on the type of product specifications and the required production speed.

High performance equipment to work with high standards and excellent production efficiency

An accessible and user-friendly design, plan for the grouping of containers, forming, filling and closing of cases in a single compact unit.

Lifting or lowering carriers are available for the rigid or flexible packing of cases and specific power systems for packaging cannot be combined with each other.

Ergonomic case store and large capacity

The machine incorporates a forced opening of the cases to ensure the correct position at the filling station and transfer to the sealing station.

Closing of cases may be effected by adhesive tape, hot glue application or combination of both systems.

CASE MAGAZINE:

Horizontal case magazine with motorized arm thereof. store length 1000 mm. As the cases are removed from the system, a case presence detector causes the progress of the tape ensuring that the product is always ready for removal. When the store is empty (or there are an insufficient number of cases for smooth operation), the machine is stopped and a visual signal warns the operator of the lack of cases. Optionally you can install an additional detection of the minimum number of cases that must always be present at the store so that the operator can reload before a machine stop.

SHAPE OF CASE:

Extraction of folded cartons using suction cups installed on a semicircular pneumatic arm Forced opening of the case by a suction cup system and a mechanism for side squaring with presence and formation detection of the case.

DRAGGING OF THE CASE:

Transporting pre-opened case to the packaging station through a system of drag chains.

INSERTION OF THE CASE:

Combined introducer group using pneumatic pusher, which with the help of a guide of the case flaps installed thereto, ensure transfer process of set of product packs into the case.

PRODUCTION:

The formation unit and closing of cases can reach an output of up to 25 cases/minute and the capacity will depend on the product and the group task to perform.

MAN/MACHINE INTERFACE:

All security or system failure elements, such as accumulation of product on the store conveyor, poorly sealed doors or protections, presence of case, malformed case, lack of air pressure, etc are displayed on a touchscreen built into the control panel for quick location. The touch screen performs the function of man/machine interface, helping to quickly solve any problems which may have occurred in machine because of two utilities: Editing of error messages. Fault location. Being an open system, the staff has access to counters, timers, etc. Without the need of specialized personnel, because of the simplicity of its use. The system offers the possibility of giving a complete history of the state of the machine: Number of cycles. Number of cases. Number of case failures. Number of introduction failures. Hours of machine running. All electrical machine command is centralized in a PLC, allowing versatility and speed or system changes.

CHARACTERISTICS

- 4 loading stations: 2 for forming, filling and closing of cases

- Occupies small amount of space

- Rapidly changes the mechanical format and stores them in a PLC.

- No introduction device in the absence of case

- Electrical and mechanical protections as per regulations

- Designed for high per minute case production

- Valid for RSC case

- Reaches an output of up to 25 cases/minute

-

Quick View

FL – 5

Devamını okuSide loading case packer designed for medium capacity

Solution for side loading, modular, compact and flexible case packer. Designed for medium per minute case production, all in a single monoblock.

The FL-5 is a side loading, modular, compact and flexible case packer, designed for medium per minute case production, all in a single monoblock

With this generation of packers, the market needs in automating the end of line products whose regular forms are readily manageable at high production volumes are catered to.

An accessible and user-friendly design, plan for the grouping of containers, forming, filling and closing of cases in a single compact unit.

Lifting or lowering carriers are available for the rigid or flexible packing of cases and specific power systems for packaging cannot be combined with each other.

Ergonomic case store and large capacity

The machine incorporates a forced opening of the cases to ensure the correct position at the filling station and transfer to the sealing station.

Closing of cases may be effected by adhesive tape, hot glue application or combination of both systems.

CASE MAGAZINE:

Horizontal case store with motor. store length 1000 mm. As the cases are removed from the system, a case presence detector causes the progress of the tape ensuring that the product is always ready for removal. When the store is empty (or there are an insufficient number of cases for smooth operation), the machine is stopped and a visual signal warns the operator of the lack of cases. Optionally you can install an additional detection of the minimum number of cases that must always be present at the store so that the operator can reload before a machine stop.

SHAPE OF CASE:

Removing the unit by folding cartons using suckers installed on a semicircular arm with mechanical movement. Forced opening of the case by a suction cup system and a mechanism for side squaring with presence and formation detection of the case.

INSERTION OF THE CASE:

Combined introducer group using pneumatic pusher, which with the help of a guide of the case flaps installed thereto, ensure transfer process of set of product packs into the case.

SEALING OF CASE:

Shifting the case to the sealing area through mechanically operated carrier

PRODUCTION:

The formation unit and closing of the cases can reach an output of up to 8 cases per minute and as a whole will depend on the product and the group to be prepared.

MAN/MACHINE INTERFACE:

All security or system failure elements, such as accumulation of product on the store conveyor, poorly sealed doors or protections, presence of case, malformed case, lack of air pressure, etc are displayed on a touchscreen built into the control panel for quick location. The touch screen performs the function of man/machine interface, helping to quickly solve any problems which may have occurred in machine because of two utilities: Editing of error messages. Fault location. Being an open system, the staff has access to counters, timers, etc. without the need of specialized personnel, because of the simplicity of its use. The system offers the possibility of giving a complete history of the state of the machine: Number of cycles. Number of cases. Number of case failures. Number of introduction failures. Hours of machine running. All electrical machine command is centralized in a PLC, allowing versatility and speed or system changes.

CHARACTERISTICS

- Two loading stations: Forming/Filling and Closing of cases

- Occupies small amount of space

- Rapidly changes the mechanical format and stores them in a PLC.

- No introduction device in the absence of case

- Electrical and mechanical protections as per regulations

- Production designed for average per minute case production

- Valid for RSC case

- Reaches an output of up to 8 cases/minute

-

Quick View

FL- 1

Devamını okuSide loading packer for medium load capacities

Solution for side loading, modular, compact and flexible case packer. Designed for medium per minute case production, all in a single monoblock.

The FL-1 is side loading, modular, compact and flexible packer, designed for medium per minute case production, all in a single monoblock

With this generation of packers, the market needs in automating the end of line products whose regular forms are readily manageable at high production volumes are catered to.

An accessible and user-friendly design, plan for the grouping of containers, forming, filling and closing of cases in a single compact unit.

Lifting or lowering carriers are available for the rigid or flexible packing of cases and specific power systems for packaging cannot be combined with each other.

Ergonomic case store and large capacity

The machine incorporates a forced opening of the cases to ensure the correct position at the filling station and transfer to the sealing station.

Closing of cases may be effected by adhesive tape, hot glue application or combination of both systems.

CASE MAGAZINE:

Horizontal case store with motor. store length 1000 mm. As the cases are removed from the system, a case presence detector causes the progress of the tape ensuring that the product is always ready for removal. When the store is empty (or there are an insufficient number of cases for smooth operation), the machine is stopped and a visual signal warns the operator of the lack of cases. Optionally you can install an additional detection of the minimum number of cases that must always be present at the store so that the operator can reload before a machine stop.

SHAPE OF CASE:

Removing the unit by folding cartons using suckers installed on a semi-circular arm with mechanical movement. Forced opening of the case by a suction cup system and a mechanism for side squaring with presence and formation detection of the case.

INSERTION OF THE CASE:

Combined introducer group using pneumatic pusher, which with the help of a guide of the case flaps installed thereto, ensure transfer process of set of product packs into the case.

PRODUCTION:

The case placement and sealing unit can reach an output of up to 10 cases per minute and as a whole will depend on the product and the set of products to be packed.

INTERFACE HOMBRE / MÁQUINA

All security or system failure elements, such as accumulation of product on the store conveyor, poorly sealed doors or protections, presence of case, malformed case, lack of air pressure, etc. are displayed on a touchscreen built into the control panel for quick location.

The touch screen performs the function of man/machine interface, helping to quickly solve any problems which may have occurred in machine because of two utilities:

Editing of error messages. Fault location. Being an open system, the staff has access to counters, timers, etc. without the need of specialized personnel, because of the simplicity of its use. The system offers the possibility of giving a complete history of the state of the machine: Number of cycles. Number of cases. Number of case failures. Number of introduction failures. Hours of machine running. All electrical machine command is centralized in a PLC, allowing versatility and speed or system changes.

CHARACTERISTICS

- Two loading stations: Forming/Filling and Closing of cases

- Occupies small amount of space

- Rapidly changes the mechanical format and stores them in a PLC.

- No introduction device in the absence of case

- Electrical and mechanical protections as per regulations

- Production designed for average per minute case production

- Valid for RSC case

- Reaches an output of up to 10 cases/minute

-

Quick View

Force And Torque Sensor

Devamını okuPerfect for tasks that require precision such as finishing, product testing, assembly, and precise part insertion.

Characteristics

Easy to use

- Plug + Play

- UR + certified products

- Free programming software

Ready for force sensitivity tasks

- Assembling and inserting parts

- Finishing parts

- Machine supervision and product verification

For industrial needs

- All-metal hardware

- Non-wear sensing technology

- High resolution sensor

Perform high-precision assembly tasks

- Use our free, ready-to-use software programs

Program your robot in seconds

- Program complex robotic trajectories in no time

- specs

- Measuring range:

FX FY: +/- 300 N

FZ MX: +/- 30 Nm

MY MZ: +/- 30 Nm - Overload capacity:

FX FY: 500%

FZ MX: 500%

MY MZ: 500% - Signal noise:

FX FY: 0.1 N

FZ MX: 0.005 Nm

MY MZ: 0.003 Nm - Recommended threshold for contact detection:

FX FY: 1 N

FZ MX: 0.02 Nm

MY MZ: 0.01 Nm - Tool deviation at maximum measurable load:

FX FY: 0.01mm

FZ MX: 0.17 degree

MY MZ: 0.09 degree - Sensitivity to external noise:

FX FY: 0.01mm

FZ MX: Immune

MY MZ: Immune - Data output rate (data stream mode):

FX FY: 100 Hz

FZ MX: 100 Hz

MY MZ: 100 Hz - Mass:

FX FY: 300 g

FZ MX: 300 g

MY MZ: 300 g - Communication protocol:

FX FY: Modbus RTU / Data stream (RS-485)

FZ MX: Modbus RTU / Data stream (RS-485)

MY MZ: Modbus RTU / Data stream (RS-485)

-

Quick View

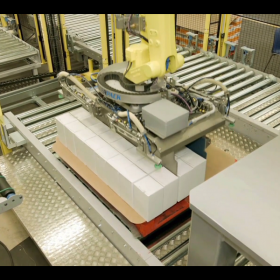

G-201

Devamını okuRobotic palletizing station with dual manual input & output

Robotic palletizing solution with dual loading station. Compact and flexible manual pallet feeding and withdrawal on one monoblock.

The G-201 palletizer has been specifically designed to handle cartons, shrink-packs or any other containers on a regular basis in a small area size

The G-201 is a robotic palletizer which has dual loading station and manual loading and unloading of pallet.

The G-201 palletizer has been designed to be directly coupled with one or two output conveyors of the packer, thus completing the end of line.

This unit is ideal for high, low and medium capacities.

It allows simultaneous working with cases and tiles of different sizes in the following sequences:

Single case conveyor. In this case, the palletizer with two pallet spaces, on completing pallet, automatically moves to the position of the second pallet to complete the process.

Multiple case conveyors with different SKUs. The G-201 palletizer positions the case on each corresponding pallet, according to the accumulation or presence of case on the conveyor.

In both cases, the positioning of the empty pallet (the loading position) and removal of the filled pallet can be carried out manually. Access to both palletizing stations may be open, but always protected by a light barrier with “muting” option.

The “inside-out” sign allows you to retrieve the pallet while anything that interferes with the “outside-in” movement activates the emergency stop. The safety of this mechanism is fully guaranteed and adheres to the EC rules.

The head is adapted to each case. However, there are three main universal fastening systems: Tweezers with side pressure, multiple suction cups with Venturi effect or claws.

Perimeter protection is designed to be as compact and robust as possible. This structure provides a complete visual inspection from any zone around the machine.

The doors allow free and unhindered access inside the machine, including safety switches for stopping the robot, in case of opening.

Touchscreen

Using the touch screen is easy and simple and constantly indicates the status and position of the axes. Modification or creation of a new palletizing mosaic is carried out by the operator through the touch screen and does not require external assistance.The touch screen and PLC are scheduled as per the standard modular OMAC and PACK ML architecture. The equipment is controlled through a multi purpose touch screen, providing the operator with the information necessary for proper handling, operations, format change and adjustment. Also, through different levels of password protection on the screen, you can modify the main parameters of the equipment

Features and advantages

- Robot palletizer with 4 or 6 axes.

- You can integrate any type of robot.

- High safety standards through barriers with sensors and option of interlocking doors.

- Large work area.

- 10″ touch screen panel with mosaics schemes included.

- Open structure that allows quick and easy access for cleaning and maintenance.

- Double pallet square for manual feed

- Different provisions depending on the application and available space.

- Custom clip to handle multiple types of cases, with fast and automatic exchange.

- Creating mosaic-like formation using the touch screen: only with measures to facilitate the pallet, the system selects the most appropriate type of pallet.

- Precise positioning and filling of the pallet (to prevent misalignment).

- Editing and modification of electronic formats by the user.

-

Quick View

G-220

Devamını okuRobotic palletizer with automatic pallet input and output

Robotic palletizing solution with automatic pallet input and output.

This unit is ideal for high, low and medium capacities.

It allows simultaneous working with cases and tiles of different sizes in the following sequences:

Single case conveyor. In this case, the palletizer with two pallet spaces, on completing pallet, automatically moves to the position of the second pallet to complete the process.

Multiple case conveyors with different SKUs. The G-220 palletizer positions the case on each corresponding pallet, according to the accumulation or presence of case on the conveyor.

In both cases, the positioning of the empty pallet (at the loading position) and removal of the filled pallet can be carried out automatically. Access to both palletizing stations may be open, but always protected by a light barrier with “muting” option.

The “inside-out” sign allows you to retrieve the pallet while anything that interferes with the “outside-in” movement activates the emergency stop. The safety of this mechanism is fully guaranteed and adheres to the EC rules.

The head is adapted to each case. However, there are three main universal fastening systems: Tweezers with side pressure, multiple suction cups with Venturi effect or claws.

Perimeter protection is designed to be as compact and robust as possible. This structure provides a complete visual inspection from any zone around the machine.

The doors allow free and unhindered access inside the machine, including safety switches for stopping the robot, in case of opening.

Touchscreen

Using the touch screen is easy and simple and constantly indicates the status and position of the axes. Modification or creation of a new palletizing mosaic is carried out by the operator through the touch screen and does not require external assistance.

The touch screen and PLC are scheduled as per the standard modular OMAC and PACK ML architecture. The equipment is controlled through a multi purpose touch screen, providing the operator with the information necessary for proper handling, operations, format change and adjustment. Also, through different levels of password protection on the screen, you can modify the main parameters of the equipment

Features and advantages

- Robot palletizer with 4 or 6 axes.

- You can integrate any type of robot.

- High safety standards through barriers with sensors and option of interlocking doors.

- Large work area.

- 10″ touch screen panel with mosaics schemes included.

- Open structure that allows quick and easy access for cleaning and maintenance.

- Double pallet square for manual feed